Custom Turbocharger Setup

Parts List:

Custom Parts List:

- Crossover Tube (Turbo Inlet)

- Turbo Downpipe

- Intercooler Tubing

To-Do List:

2001 Malibu Cruiser Concept

NOTE: The Malibu and Grand Am are both GM N-Body designs. The 3500 is identical to the 3400 except for the cylinder bore. This just goes to show that this is entirely possible. Photos courtesy of N-Body.net.

homegrown's 2001 Oldsmobile Alero

Another N-body car with the exact same engine as mine. Thanks for the photos Dave!

ITS Turbo Prototype

ITS plans to sell this as a turn-key when development is complete. Thanks for the photos Brent!

NOTES:

- Provides more room for turbo install, removes battery from turbo heat

- Relocating to remove wiring from turbo heat

- I will remove the oil pan and add the appropriate amount of water to make sure I get the drain above the oil level.

- I have already remove the TB coolant lines and have a bypass hose installed. I'll just supply the turbo cartridge with coolant from these taps.

Turbocharger

All calculators in bold are available online c/o Ray Hall Turbocharging

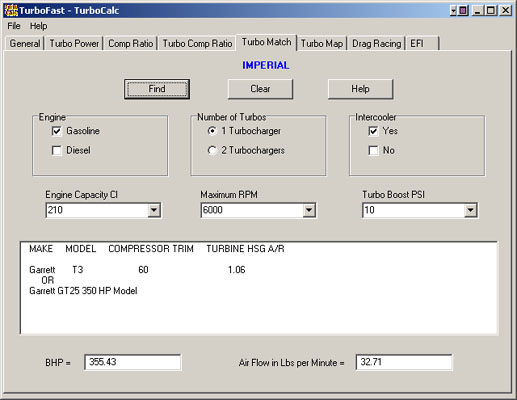

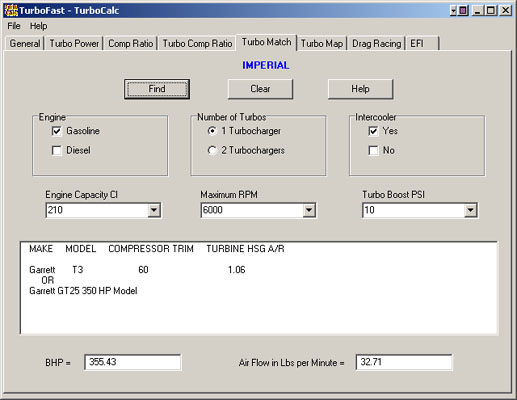

The MOST IMPORTANT aspect of turbocharging any vehicle is properly matching the turbocharger to the engine. As a baseline, I used the Turbo Match Calculator. The calculator recommended the Garrett T3 with a Compressor Trim 60, and a Turbine A/R of 1.06 (See Figure)

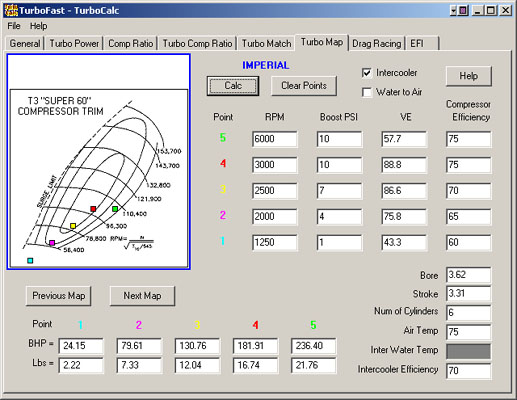

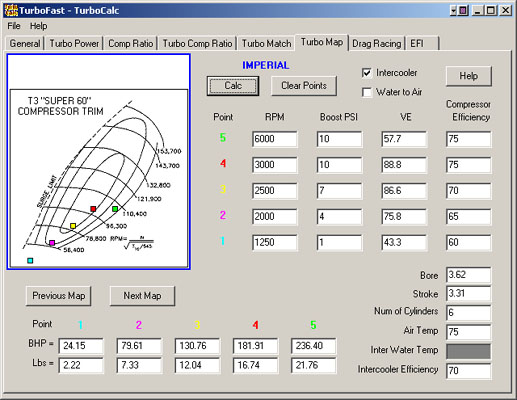

To verify this recommendation and for a little peice-of-mind, I plotted my engine flow on the Compressor Map for the T3 "Super 60" Trim. To accomplish this, you need to define the Volumetric Efficiency of the engine at the points to be plotted. To define these, I used the Engine VE Finder for the following RPM's: 1500, 2000, 2500, 3000, and 6000. The optimum matched turbo rises just shy of the surge line then flattens out at the 2/3 side of the max efficiency ring. I then plugged those numbers into the Turbo Map program to obtain the following chart:

Now I can say I am pleased with the Turbo Match recommendation! The center circle in the map represents the compressor's highest efficiency "zone". For the T3 "Super 60" Trim, this equates to 75%. The idea is to get as much of the engine flow at peak HP RPM's in this zone. I also checked these numbers against other compressor maps and this appears to be the best match without getting too close to the surge limit. The RPM band rises right up the center of the high-efficiency zone.

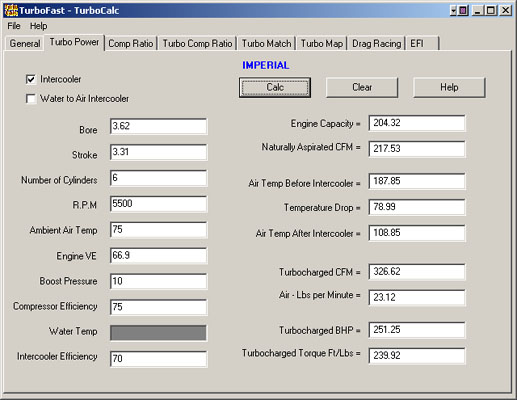

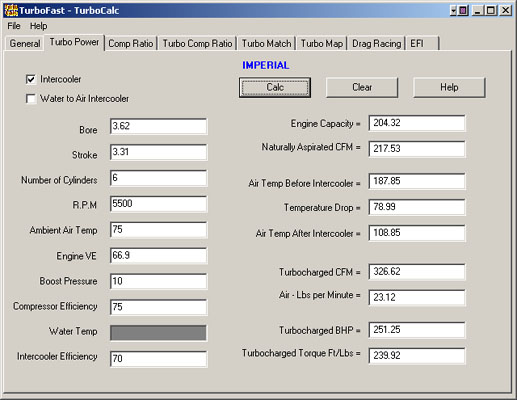

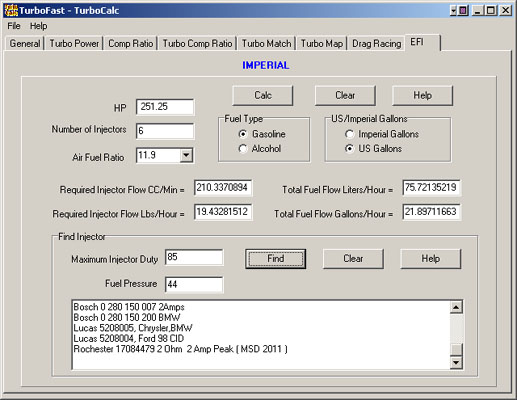

Now for the fun part ... using the Turbo Power calculator to estimate HP (See Figure)

I can live with 251.25HP! FYI, I check the Intercooler box and assume an efficiency of 70% (standard air-air effieciency).

Now the search for a Garrett T3 "Super 60" Trim begins ... The only downside to this turbo is that the "Super 60" is the largest compressor in the T3 series. I could always adapt a T4 compressor later if need be. On the turbine side, I'll probably go with a 0.82 A/R to reduce spool-up time. I'll also invest in the Stage II or Stage III turbine wheel and ceramic coating.

The advantage of using a Garrett T3/T4 is the availability of OEM and aftermarket parts. If after installing I need to increase the compressor or turbine size, there are several larger housings available as well as ball-bearing center sections, ceramic wheels, etc.

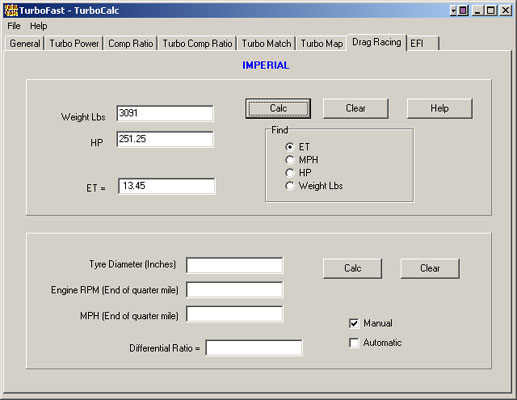

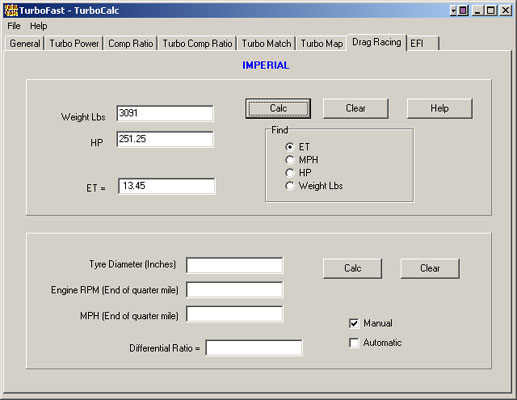

Just to make sure this turbo design will help me achieve my 12-second goal, I punched in the HP figures from above into the Drag Racing Calc:

Works for me! A set of drag radials and a shot of juice ... 12's baby!

Photos of a Garrett Turbochargers

Photographs c/o Turbonetics

|

|

|

| T3 Turbo |

T4 Turbo |

Ball-Bearing Cartridge |

Exhaust System

I had a chance to talk to a guy who has designed custom turbo systems for 25 years and I explained my intent of doing custom tubular headers. He explained that in a turbo car, they are not important unless they can be properly tuned to deliver pulses to the turbine in a sequential order. Since the turbo is fed off of both banks, he suggested to just use a "log-style" manifold. Since the factory manifolds are already "log-style", I'll just need to replace the crossover pipe with a turbo "Y", and block the current downpipe exit on the rear and re-route to the turbine exhaust.

| 3400 Manifold |

3100 Manifold |

|

|

When GM went from the 3100 to the 3400, they redesigned the rear manifold so the ports flow to the center to the downpipe. This will inhibit flow back through the crossover opening. I will replace the rear manifold from one off of a 3100 engine which is not tapered and more linear.

Engine

The GM LA1 engine is already pretty hefty as far as bottom-end components are concerned. It comes factory with a forged, internally-balanced crank and forged connecting rods. With the stock cr at 9.5:1, that limits the amount of boost I can safely run before detonation occurs.

| cr at 10psi |

cr at 7psi |

|

|

I'll be limited to about 10psi at the manifold so to prevent tearing into the already stout bottom end, that's the pressure I'll have to live with. From the charts above, 7 psi will still allow me to run at 93 octane pump gas. Since I'll have a dual-stage boost controller, I'll set normal boost to about 7psi for daily driving and then switch to 10 for race day.

Another issue with the LA1 is the stock camshaft. Turbos prefer NO overlap between exhaust and intake lobes. I do not have the exact factory specs, but for all practical purposes, it should have overlap to benefit the NA engine. Again, no one makes cams for the LA1, and since it uses a hollow core with pressed-on lobes, a custom cam would cost a small fortune. In the tune of simplicity, I'll leave the stock cam as-is. If I find later down the road that I need to squeeze a few more horses, I always have the option of a most cost effective regrind.

Another area of concern is the cylinder heads. Since forced induction heads do not require extensive porting but DO benefit from mild porting, I have installed RSM Ported 3.4L Heads which include port & polish, mild bowl porting, 3-angle valve job, and each cylinder is flow-matched. I combined these with gasket-matched upper and lower intakes and an RSM 62mm throttle body. Pics and details HERE.

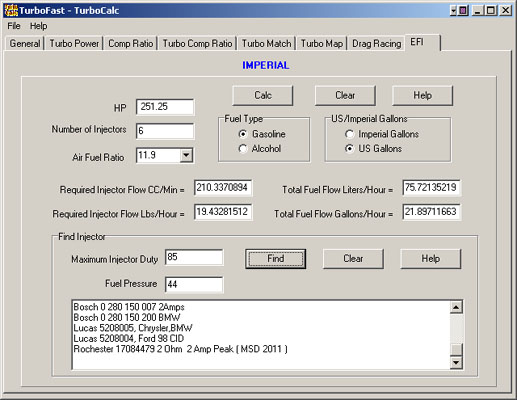

Fuel delivery is also important under boost to prevent detonation. I used TurboCalc to calculate fuel requirements under boost:

The stock 3400 injectors are set at 22.5 lb/hr, and with this considered, I'm assuming the stock fuel system is capable of providing the necessary fuel requirements without modification other than the PCM tuning. If this proves me wrong, I'll upgrade to the GM 4.2L injectors which have been proven to work in several other 3x00 engines without any problems so long as the PCM is tuned for the larger injectors vs. stock. Also, from what I have read, the stock fuel pump can supply the flow requirements of the 4.2L injectors. Instead of modifying the stock PCM tables and spending a fortune on the dyno and renting a programmer, I will use the Greddy Rebic IV Sub-Injector Computer to supply extra fuel based on a boost/RPM/fuel table.

Battery Relocation

In order to make more room for the turbo to be installed, I needed to relocate the battery to the trunk and also trim the airbox bracket so that it just held the fuse center in place.

Gauges & Controls

As with any forced induction system, I will need to be able to monitor a few important parameters:

- Boost/Vacuum

- Air/Fuel Ratio

- Exhaust Gas Temperature (EGT)

- Transmission Temperature

Lotek makes a 2 and 3-gauge pod for the 99+ Grand Am. Seeing that I need 3 aftermarket gauges (EGT, Boost Pressure, Transmission Temp), that narrows down my choices. I will mount the air/fuel monitor in the console where I can keep my eye on it at all times.

As I am tweaking and tuning the system, I need to adjust the boost pressure. I decided to use the TurboXS Dual-Stage Boost Controller. This controller allows 2 modes of boost (Lo & Hi). Lo will be tuned between 5-9 psi for daily driving, Hi between 10-14 for performance (RACE ONLY). The benefit of this controller is that switching between these 2 modes can be done with the flick of a switch even at full boost! I am also adding a Greddy Turbo Timer to protect the turbo bearings and ensure proper cool-down.

For safety, I am also adding a TurboXS Blow-Off Valve Type-s.

Boost Modifications

Certain accessories require vacuum to operate and I do not want to pressurize these lines under boost conditions. I have obtained a copy of the Magna-Charger Installation Manual to help me determine which lines need re-routed.

- MAF Sensor - Placed pre-turbo

- IAT Sensor - Placed pre-turbo

- MAP Sensor - Will work fine under boost

- EGR Valve - Only opens under vacuum, so not a concern

- EVAP Sensor - Needs check valve

- FPR - Will work fine under boost

- PCV - Convert to open-element breather

- Brake Booster - Needs check valve

Miscellaneous

Intercooler

Physics taught us that as air is compressed, the temperature rises. To prevent 200+ degree air from feeding the engine and reducing the positive effects of the turbo, an intercooler needs to be added. In order to reduce costs, I'll be using the factory intercooler from a 1987 Toyota Supra Mk3. This intercooler has been tested many times online and flows better than almost any other factory intercooler out there.

From top to bottom: Supra Mk3, Starion/Conquest, Spearco

Chassis Mods

Another area of concern with this much horsepower is suspension. Why? Well, horsepower in turn makes the car faster, but the most common thing overlooked is the suspension capable of handling the extra horsepower. I don't know if you have ever driven a stock Grand Am, but there is definitely room for improvement! ;-)

My suspension plans include:

- Eibach Pro-Kit Springs

- Mantapart Sport Struts

- TNL Strut Tower Braces

- TNL Swaybars

- 17" Wheels and tires (currently 15")

- Rear Disc Brake Conversion

BACK

Puerto Rico Party Bus and Tampa Party Bus